ShaftDesigner shaft alignment and vibration calculation software

ShaftDesigner shaft alignment and vibration calculation software

Pioneer in shaft alignment and shaft vibration analysis software worldwide

ABOUT software

Shaftdesigner software is jointly developed by engineers from Ukrainian Black Sea Shipyard and professors from Ukrainian National Shipbuilding University. It is a perfect combination of practical experience and theoretical simulation analysis. The software was first developed in 1986 and is the pioneer of shaft alignment and shaft vibration analysis software worldwide. After decades of continuous development and improvement, it has become the current version. Now it has been widely used in major classification societies, major European ship design units, main engine design and production units, gearbox design and production units, power propulsion system design or power system integration units, and some shipyards and ship maintenance and repair units.

Modeling advantages

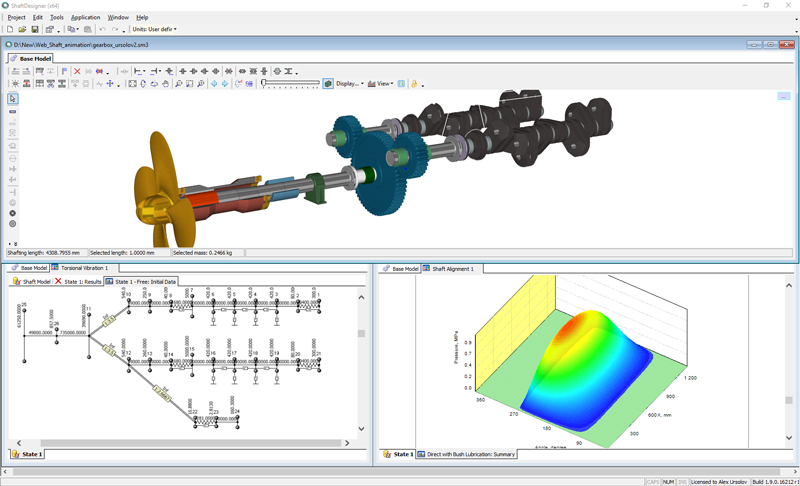

1. Shafting 3D modeling, the model can be created by simply dragging and dropping, making modeling more convenient and intuitive.

2. The anisotropic bearing model can be used to calculate the whirling vibration.

3. With its own model database, the created model can be stored in the model library to provide reuse for other projects.

Advantages of School Computing

1. Automatically calibrate the model and support the calibration design under various working conditions.

2. The industry's only tool software that supports the reverse calculation of ship shaft alignment, a good news for ship maintenance engineers.

3. When calculating the shaft alignment, the software can support the calculation of single-point support model and multi-point support model calculation.

4. Mature dynamic calibration calculation support, which can simultaneously consider the effects of ship double bottom structure deformation, bearing water lubrication and oil film pressure parameters.

Vibration calculation advantages

1. Support the time-domain transient calculation and analysis of shafting torsional vibration under the latest ice zone environmental standards; the software comes with different ice thickness levels for selection.

2. Support vibration calculation for multi-stage gear structure.

Other advantages

1. Support automatic identification and import of host incentive data from host manufacturers such as MAN and Wärtsilä, and provide default experience value reference for customers when they do not have host incentive data values;

2. Support modeling calculations for fixed propellers and controllable propellers, the software supports the calculation of primary and secondary excitations for the propeller, and supports the custom setting of the number of propeller blades. The department chooses to provide the default propeller excitation experience value reference;

3. Support the setting of multiple classification societies standards, and automatically calculate whether they meet the current classification societies standards.

4. The same software platform covers all calculation functions required for shaft alignment and vibration. The software has a friendly human-computer interaction interface and a high-speed solver based on finite element algorithm, which greatly improves the work efficiency of marine engineers.

- Classification Society

- Ship overall design unit

- Ship propulsion system design and integration

- Marine main engine design and manufacturing unit

- Marine propeller design and manufacturing unit

- Marine gearbox design and manufacturing unit

- Design and manufacturing unit of shaft connection components (such as bearings, bushings, flanges, couplings, high elastic, etc.)

- Shipbuilding plant

- maintenance/overhaul unit

The main function

ShaftDesigner- is a professional CAE simulation software dedicated to shaft alignment and vibration calculations during the design, manufacturing and maintenance stages of ship propulsion systems. The main functional modules are as follows:

Basic 3D modeling module

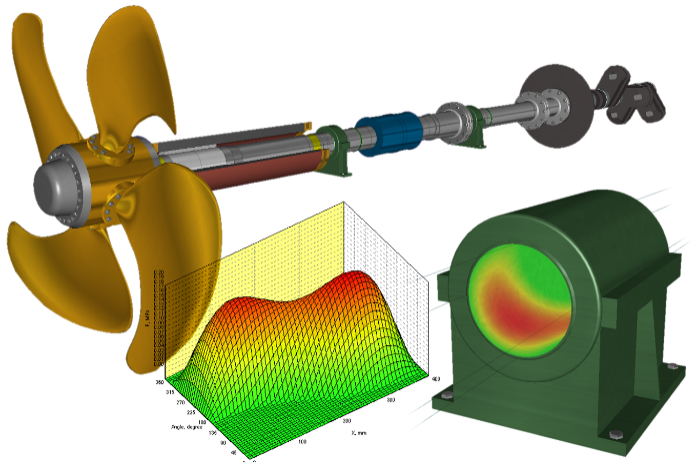

- Basic 3D modeling module. The software provides a 3D modeling environment, which can quickly and accurately model the shaft system designed by the user. The model created can be composed of multiple shafting, engine crankshaft, gearbox, fixed or adjustable propeller, stern tube, bracket, different types of flanges and bearings. The model created by this module is the basis for supporting various subsequent calculations. The created model can be directly saved in the model library and can be called at any time.

Shaft alignment calculation module

- Provide shaft alignment calculation and bearing load analysis of ships under various loading conditions. Both vertical and horizontal bending calculations can be considered, and the bearing models of irregular-shaped bushes can also be modeled and analyzed. This module can realize a complete shaft alignment calculation process cycle: for example, the current bearing displacement is determined by the reverse calculation method, and the best displacement value of the bearing under the loading state of the ship is obtained. The calculation results are checked by methods such as shift deflection measurement and strain gauge measurement. Additional functions: bearing contact pressure distribution, bearing hydrodynamic lubrication, propeller load, gear tooth load, hull deformation estimation, process tolerance calculation.

Gyroscopic vibration calculation module

- The bearing adopts an anisotropic model, that is, bearing stiffness and damping have direction and frequency dependence. It can calculate the damping natural frequency, mode shape and critical speed of the free vibration of the shaft system, and generate a Campbell diagram. Harmonic response analysis can provide various parameters of any part of the shaft system, and display whether the current critical speed will cause abnormal vibrations in three-dimensional animation. Rotational vibration is related to shaft alignment parameters and bearing operating state, which provides a more accurate prediction for the dynamic characteristics of shafting.

Axial vibration calculation module

- The calculation of free axial vibration can significantly reflect the modal vibration shape of the shaft system under various critical speed conditions. Harmonic response analysis can truly reflect the shaft displacement and thrust bearing load of the equipment at operating speed. This module supports the setting of excitation, frequency, stiffness and damping parameters for all equipment models.

Torsional vibration calculation module

- Generate a calculation plan based on the size of the shaft. It can carry out calculation of angular displacement and deformation between components, calculation of vibration torque and stress in shafting components, analysis of hammering effect caused by gear meshing, calculation of power loss of flexible components and dampers, calculation and analysis of diesel engine normal operation and shutdown state. The advanced ice zone enhancement and short-circuit analysis functions can provide time-domain transient analysis functions and support the latest standards proposed by various classification societies.