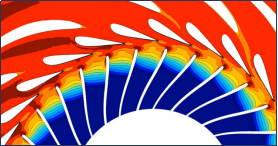

Simcenter STAR-CCM+ computational fluid analysis software

Simcenter STAR-CCM+ computational fluid analysis software

Combining modern software engineering technology, the most advanced continuum mechanics numerical technology and excellent design, it integrates the latest achievements and experience of Siemens in the field of CFD engineering consulting for many years.

ABOUT software

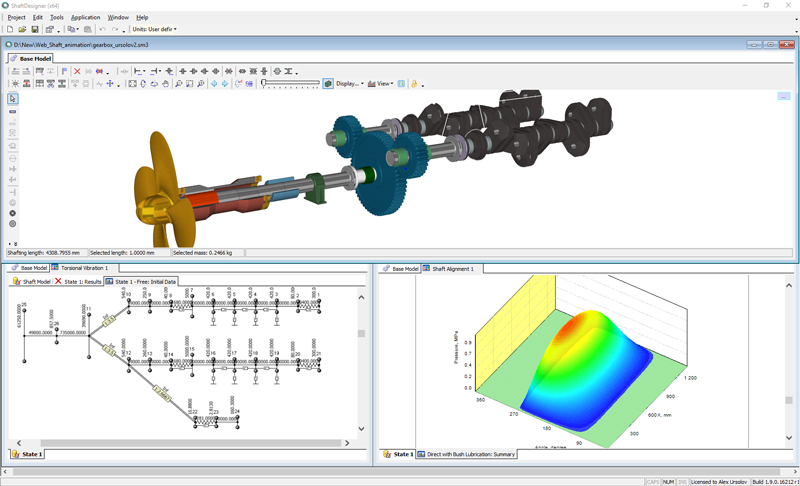

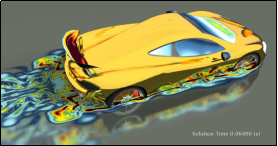

For products and designs that work under real conditions, STAR-CCM+ is a new generation of CFD software under the Siemens Group. It combines modern software engineering technology, the most advanced continuum mechanics numerical technology and excellent design, and integrates the latest achievements and experience of Siemens in the field of CFD engineering consulting for many years. Simcenter STAR-CCM+ is a complete multiphysics solution for simulation. Its uniqueness is that Simcenter STAR-CCM+ brings automated design exploration and optimization to each engineer’s simulation toolkit, allowing them to efficiently explore the entire design space instead of focusing on a single point design scenario.

Integrated working environment, integrated graphical user interface, integrated pre-processing and calculation analysis in the same environment

STAR-CCM+ can realize large-scale parallel computing of about 1 billion grids, and also realizes the multi-CPU parallel function in front and rear processing.

The polyhedral mesh of STAR-CCM+ is as accurate as the hexahedral mesh, and it is as easy to generate and automatically generate as the tetrahedron. It is now mature to apply polyhedral mesh to engineering calculations

The Couple solver of STAR-CCM+ is more accurate for solving supersonic shock waves, natural convection and other engineering problems with strong coupling of velocity, pressure and temperature

STAR-CD/CCM+ uses the same solver to solve flow field, thermal and thermal stress analysis problems: linear stress and small deformation problems

The new surface wrapper function (surface wrapper) can automatically convert the complex and broken CAD model in the engineering case into a closed grid, saving a lot of CAD data manual repair time; automatically generate polyhedral mesh, tetrahedral mesh and Hexahedral mesh without manual intervention; advanced functions such as surface feature maintenance and simplification, contact prevention, leak inspection, automatic or manual surface repair

Multi-physics, continuum-based modeling method. When modeling, define the fluid or solid "continua" and carry the grid and calculation method; the solution domain is divided into various "regions" and carry the physical space. The area will be assigned to a continuum, and different physical spaces can be assigned different calculation methods.

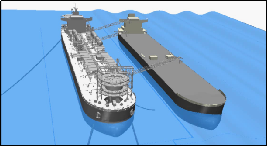

STAR-CCM+ is currently used in almost all important industrial and research fields such as automobile, aviation, aerospace, nuclear engineering, electric power, electronics, petroleum, chemical industry, shipbuilding, household appliances, railways, water conservancy, construction, and environment. Thousands of users.

For example: free surface flow resistance analysis of surface ships, integrated analysis of propeller/rudder, water jet propulsion technology, cavitation/cavitation analysis, cavitation weapon system, underwater weapon launch, ship noise analysis, interior of conventional/nuclear powered ships Thermal analysis

Nuclear power reactor core radiation/heat analysis, water/sodium cooling pipeline

The main function

Combining modern software engineering technology, the most advanced continuum mechanics numerical technology and excellent design, the main functional modules are as follows:

Basic 3D modeling module

- Perform virtual simulation of electrochemical model to deeply understand and predict electrochemical phenomena in real environment.

Computational fluid dynamics simulation

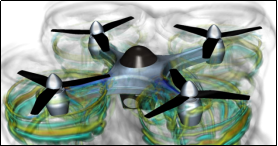

- Provides the industry's cutting-edge computational fluid dynamics software, users can simulate any engineering problem including liquids, structures, and all related physics.

CFD simulation of moving objects

- Accurately capture the physical movement of objects. Through the establishment of a motion model for simulation calculations, the dynamic 6-DOF motion of objects is predicted, and the physical interaction of multiple objects is understood.

Battery simulation

- Digital verification of lithium-ion battery design, including geometric battery specifications and battery performance. A large number of components and material databases of battery cells are available for users to use in their model development.

Co-simulation

- Connect to other simulation tools through dedicated interfaces or intuitive APIs. This enables multi-physics simulations with different time scales ranging from microseconds to thousands of seconds, and can provide faster, more accurate analysis and shorter conversion times for the development and evaluation of complex designs.

Motor simulation

- The comprehensive analysis model includes all aspects of motor design, including thermal, electromagnetic and drive control. Of particular importance is the effective use or even elimination of magnets. Our simulation tools are structured to provide seamless design capabilities across the entire permanent magnet motor series and alternatives including hybrid combinations, and cover the entire power, voltage and speed range used in vehicle systems.

Engine simulation

- Engine simulation involves moving parts, multiphase flow, combustion and heat transfer. You no longer need to be an expert user to simulate internal combustion engines: using application-specific workflows and simplified interfaces, engine simulations can be set up quickly and easily. Expert users can use these simulations as a starting point for more complex multi-physics engine simulations that take advantage of the full set of simulation capabilities of Simcenter STAR-CCM+.

Four-point slewing ring calculation

- Large slewing bearings use different bearing types: one or two rows of four-point bearings and three sets of roller bearings. The software can analyze the configuration of one or two rows of four-point bearings. The important results are contact stress, friction moment and shear stress under the surface to determine the necessary hardness depth. According to NREL DG03 life and static safety calculation guidelines, the hardness of the seat ring should be reduced. The calculated contact stress id at all four (or eight) contact points. So the user can see if the 4-point contact occurred and how often. In a calculation using the load spectrum, multiple load cases can be considered.

Solid mechanics simulation

- Almost all practical engineering problems ultimately depend on the interaction between fluid and solid structure. Simcenter STAR-CCM+ provides finite volume (FV)-based computational fluid dynamics and finite element (FEM)-based computational solid mechanics (CSM) in an easy-to-use single integrated user interface. Using this method, you can solve static, quasi-static, and dynamic problems, including problems with nonlinear geometries, as well as problems with multiple parts that use bonding and small sliding contacts.